In the world of construction, mining, and industrial work, heavy machinery is the backbone of operations. At the heart of every machine lies its engine, a critical component that determines performance, efficiency, and longevity. Whether you’re investing in a new engine or considering a used one, understanding the differences is essential for making a cost-effective and reliable choice.

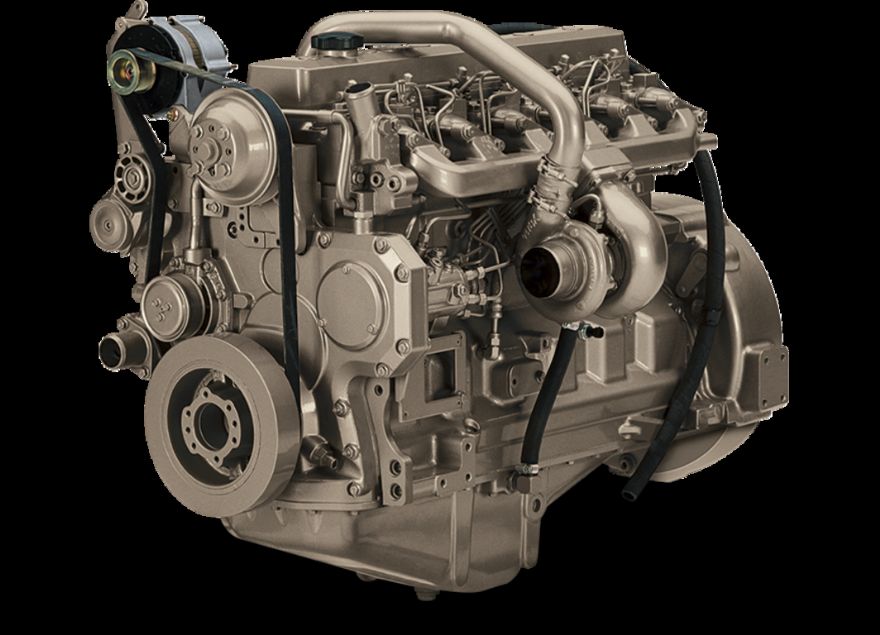

New Heavy Machinery Engines

Purchasing a new engine offers several advantages. Firstly, a new engine comes with the latest technology, which often means better fuel efficiency, lower emissions, and improved overall performance. Manufacturers typically provide warranties on new engines, giving you peace of mind in case of unexpected defects or issues. Additionally, new engines require less immediate maintenance, reducing downtime and repair costs in the initial years.

Brand new WP12.430E50 National V engine for Shaanxi Automobile 6x4 trucks

However, the primary drawback is cost. New engines can be significantly more expensive than used ones, especially for large-scale heavy machinery like excavators, bulldozers, or industrial trucks. For companies on a tight budget or those operating on short-term projects, this high upfront cost can be a major consideration.

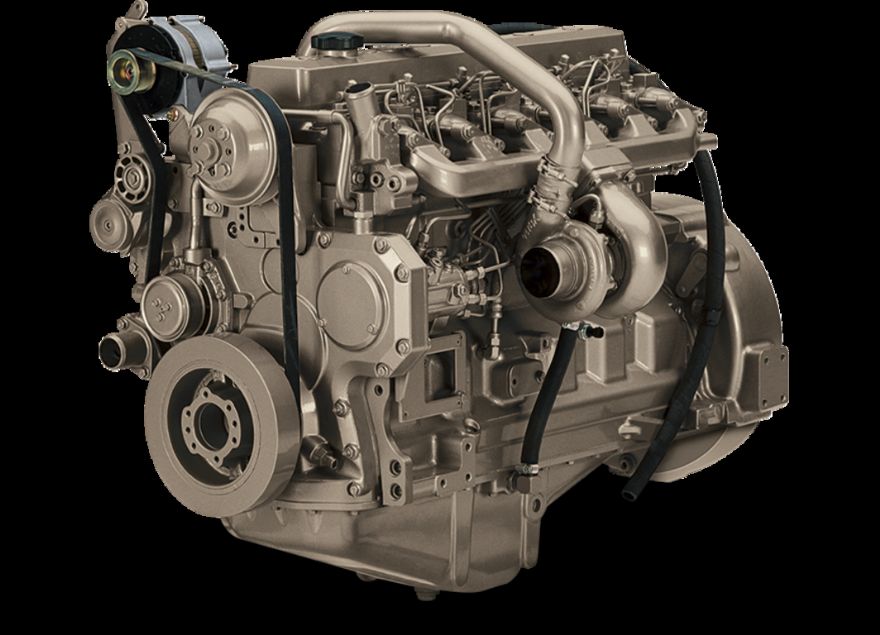

Used Heavy Machinery Engines

Used engines, on the other hand, offer affordability. They can be a practical option for businesses that want to reduce initial expenses while still keeping machinery operational. Many used engines are refurbished or rebuilt, meaning they have been repaired or upgraded to restore performance and reliability.

The risks with used engines include potential hidden wear and tear, reduced efficiency compared to new models, and shorter remaining lifespan. Proper inspection and sourcing from reputable dealers are critical to minimize these risks. Some suppliers offer limited warranties or service agreements for used engines, which can add a layer of security for buyers.

Factors to Consider When Choosing

When deciding between a new or used heavy machinery engine, consider the following:

Budget: How much capital can you allocate upfront versus over the engine’s lifecycle?

Usage: High-intensity or long-term projects may benefit more from new engines, while short-term or less demanding operations might suit used engines.

Availability of Parts: Older or discontinued engines may have limited replacement parts.

Warranty and Support: Check the warranty terms and service support available for both options.

Conclusion

Both new and used heavy machinery engines have their pros and cons. New engines provide reliability, advanced technology, and longer-term peace of mind, while used engines offer affordability and quicker access to machinery. By carefully evaluating your operational needs, budget, and the engine’s condition, you can make a choice that ensures productivity and minimizes downtime.

Investing in the right engine is not just about immediate cost—it's about ensuring your machinery runs efficiently and effectively for years to come.